SABYDOMA Project starts!

Safety BY Design Of nanoMAterials - From Lab Manufacture to Governance and Communication: Progressing Up the TRL Ladder (SABYDOMA)

This week has seen the EU H2020 SABYDOMA Project Kick-Off Meeting, held telematically due to the covid-19 pandemic situation, in which Applied Nanoparticles SL has a leading role as Work Package Leader and primary industry site where to implement the SABYDOMA's lead demonstrator

Project summary & objectives:

SABYDOMA Project addresses developments in the safety by design (SbD) paradigm by examining four industrial case studies in detail where the TRLs will advance from 4 to 6. Each TRL activity will progress from being lab based at TRL4 to being industry based at TRL6. The TRL4 activity will involve only innovation with regular industrial communication whereas the TRL6 activity will involve industrially located activities with innovation communication. One of the novel themes of this study is to use system control and optimisation theory including the Model Predictive Control (MPC) philosophy to bind the whole subject of SbD from laboratory innovation to the industrial production line and from decision making processes to project governance. An equally important innovative step is the building of high throughput online platforms where nanomaterial (NM) is manufactured and screened at the point of production. The screening signal controls the NM redesign and production in a feedback loop. Screens will involve (a) physiochemical sensing elements (b) in-vitro targets of increasing complexity from the 2D biomembrane to cell-line and more complex cell-line elements; and, (c) multiple in-vitro targets with multiple end-points; developed in current H2020 projects. Two of the industrial studies include composite coating manufacture where the coating’s stability and toxicity will be tested using a flow through microfluidic flow cell system coupled to online screens. This is part of the release and ageing investigations on the NM and NM coatings and the results of these will feed back to the production line design. At every step on the TRL ladder the in-silico modelling will be applied to optimise and redefine the relevant activities. By the same token regulatory and governance principles of SbD will be used to refine the technological development. The final deliverable will be four distinct technologies applying SbD to the four industrial processes respectively.

Project Details:

Coordinator: University of Leeds (UK)

Number of partners: 19 beneficiaries

Project duration: 01 04 2020 - 30 09 2023 (42 months)

Total cost: EUR 7.105.520

EU contribution: EUR 5.969.751,25

SABYDOMA project has received funding from the European Union’s HORIZON 2020 research and innovation programme under grant agreement n°862296.

For further information on SABYDOMA Project visit http://www.sabydoma.eu/ (currently under construction)

Notebook nº2 of Nanocolouring in times of coronavirus is now available !

From the field of nanotechnology we want to make our contribution in the collective effort against the covid-19 pandemic. For doing so, we want to reach out to the little ones and their families. Following the good feedback obtained from the first volume of Nanocouloring in times of coronavirus (see its press release here ), we have just published a new volume, Notebook nº2, in colaboration with the colombian Nanoscale Science and Technology Center (nanoCiTec) with which we are partners in the BIP-CO Project.

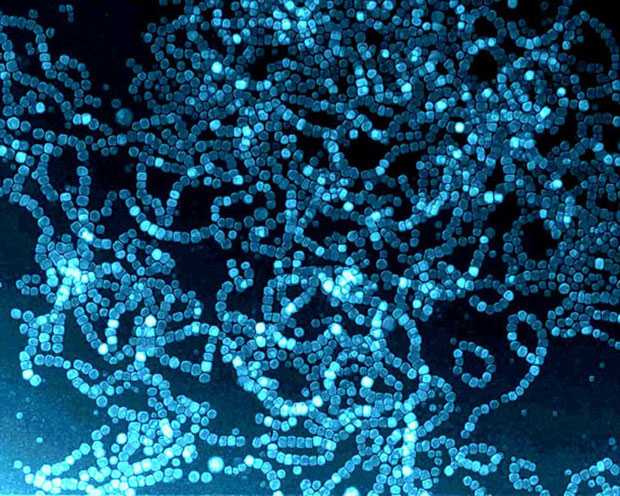

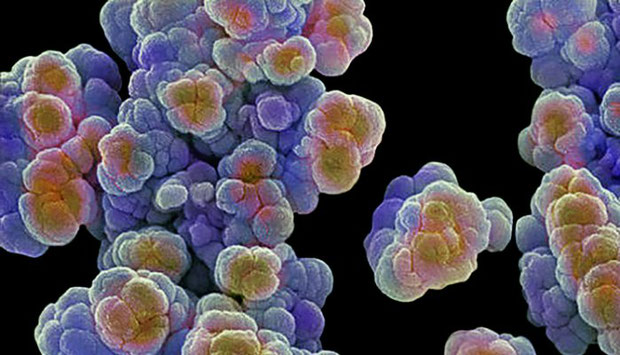

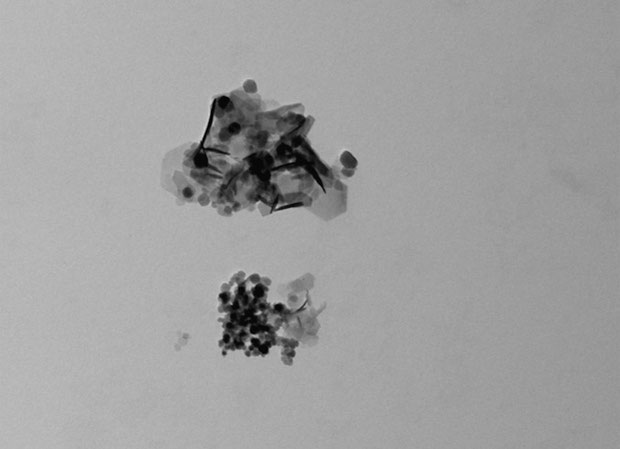

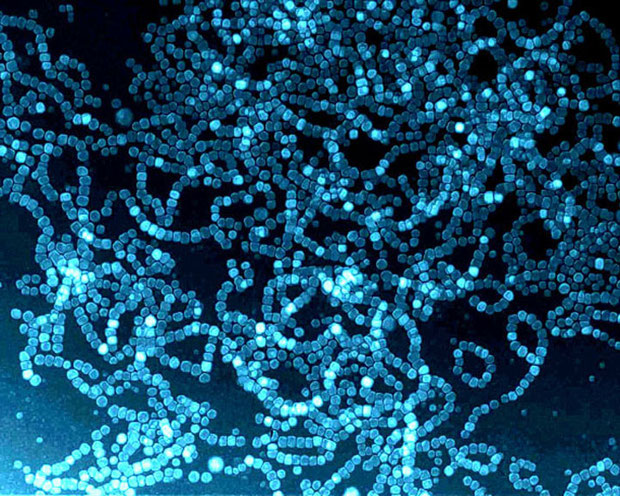

In this second Notebook we present an introduction to Nanotechnology with different materials created by Dr. Edgar E. González (IP at nanoCiTec and professor at the Pontificia Universidad Javeriana). And we try to entertain them through a set of sheets for nanocolouring, painting and scribbling made up of images of inorganic nanoparticles extracted by Dr. Víctor Puntes (researcher at the Institut Català de Nanociència i Nanotecnologia -ICN2-, the Vall d'Hebron Institute of Research –VHIR- and the Institut Català de Recerca i Estudis Avançats -ICREA-) when observing with an electron microscope.

Both NanoColorea en tiempos de Coronavirus (in spanish) volumes can be freely downloaded at:

https://www.nanocitec.org/nanocolorea/

For further information on Nanocouloring in times of coronavirus: Notebook nº2 visit:

https://www.biogasplus.info/nanocolorea-esp/nanocolorea-2-eng/

For further information on the BIP-CO Project visit https://www.biogasplus.info/bip-co-project/

Nanocolouring in times of Coronavirus. Notebook 1

In the face of the health emergency caused by COVID-19, and within the framework of the European BIP-CO project, Applied Nanoparticles SL and the Nanoscale Science and Technology Center –nanoCiTec- have developed the book <<NanoColorea en tiempos de Coronavirus>> a set of materials to entertain, inform and educate the youngest and their families, at the intersection of the viral pandemic and the world of nanotechnology. An action to contribute to the collective effort against the pandemic and make #YoMeQuedoEnCasa more bearable in Colombia and worldwide.

NanoColorea en tiempos de Coronavirus can be freely downloaded at:

https://www.nanocitec.org/nanocolorea/

For further information on NanoColorea en tiempos de Coronavirus notebook visit:

https://www.biogasplus.info/nanocolorea-esp/nanocolorea-eng/

For further information on the BIP-CO Project visit https://www.biogasplus.info/bip-co-project/

Start of BIP-CO Project

Applied Nanoparticles SL (spin off from The Instituto Catalán de Nanociencia y Nanotecnología –ICN2-, la Universidad Autónoma de Barcelona –UAB- y el Institut Català de Recerca i Estudis Avançats –ICREA-) and the Centro de Ciencia y Tecnología Nanoescalar –nanoCiTec- will start from the 1st of November 2019, and with a duration of six month, the Project <<BIP-CO: Introduciendo la nanotecnología en el sector del biogás en Colombia>> funded under the R&I Programme Horizon 2020 from the EU through the INNOWIDE Project.

For further information on the BIP-CO Project visit: https://www.biogasplus.info/bip-co-project/

New uses of Magnetite Nanoparticles, the active principle of BioGAS+

Two scientific publications in Nature and Nature Nanotechnology highlight the more medical uses of ferumoxytol, an FDA-approved iron supplement based, as our BioGAS+, on magnetite nanoparticles.

The two potential medical uses reported are: prevention of tooth decay and inhibition of tumour growth by inducing pro-inflammatory macrophage polarization in tumour tissues (specifically liver tumours). These extends the potiental uses of both our Fe3O4NPs-based product BioGAS+ and our Fe3O4NPs colloids, offered with different specifications within our Pandora Nanoparticles Menu and Nanoparticles Atelier, further than the already well-known use as supplement for iron-deficiency anemia.

Topical ferumoxytol nanoparticles disrupt biofilms and prevent tooth decay in vivo via intrinsic catalytic activity

Abstract: Ferumoxytol is a nanoparticle formulation approved by the U.S. Food and Drug Administration for systemic use to treat iron deficiency. Here, we show that, in addition, ferumoxytol disrupts intractable oral biofilms and prevents tooth decay (dental caries) via intrinsic peroxidase-like activity. Ferumoxytol binds within the biofilm ultrastructure and generates free radicals from hydrogen peroxide (H2O2), causing in situ bacterial death via cell membrane disruption and extracellular polymeric substances matrix degradation. In combination with low concentrations of H2O2, ferumoxytol inhibits biofilm accumulation on natural teeth in a human-derived ex vivo biofilm model, and prevents acid damage of the mineralized tissue. Topical oral treatment with ferumoxytol and H2O2 suppresses the development of dental caries in vivo, preventing the onset of severe tooth decay (cavities) in a rodent model of the disease. Microbiome and histological analyses show no adverse effects on oral microbiota diversity, and gingival and mucosal tissues. Our results reveal a new biomedical application for ferumoxytol as topical treatment of a prevalent and costly biofilm-induced oral disease.

Topical ferumoxytol nanoparticles disrupt biofilms and prevent tooth decay in vivo via intrinsic catalytic activity

Abstract: Until now, the Food and Drug Administration (FDA)-approved iron supplement ferumoxytol and other iron oxide nanoparticles have been used for treating iron deficiency, as contrast agents for magnetic resonance imaging and as drug carriers. Here, we show an intrinsic therapeutic effect of ferumoxytol on the growth of early mammary cancers, and lung cancer metastases in liver and lungs. In vitro, adenocarcinoma cells co-incubated with ferumoxytol and macrophages showed increased caspase-3 activity. Macrophages exposed to ferumoxytol displayed increased mRNA associated with pro-inflammatory Th1-type responses. In vivo, ferumoxytol significantly inhibited growth of subcutaneous adenocarcinomas in mice. In addition, intravenous ferumoxytol treatment before intravenous tumour cell challenge prevented development of liver metastasis. Fluorescence-activated cell sorting (FACS) and histopathology studies showed that the observed tumour growth inhibition was accompanied by increased presence of pro-inflammatory M1 macrophages in the tumour tissues. Our results suggest that ferumoxytol could be applied ‘off label’ to protect the liver from metastatic seeds and potentiate macrophage-modulating cancer immunotherapies.

The Nanoparticles Atelier by Applied Nanoparticles is up and running

The Nanoparticles Atelier intend to provide the most commonly used nanoparticles (NPs) at decent cost and larger amounts than employed for in vitro experiments to address, among other, in vivo and ecotoxicity studies and nanoenabled products development.

We produce these NPs everytime new, under request, once an order is accepted. We always keep aliquots of the synthesis employed to prepare your sample for later checking on aging and stability.

Our expertise steems after years of research on the synthesis of inorganic NPs, we have knowledge on the production of many different metallic (as Au, Ag, Pt, Pd, Fe, Co, Ni), oxide (LuO, CuO, PbO, and semiconductor NPs (CdSe, CdTe, …), as much as heterodimmers (as Au-CeO2, Ag-TiO2) and multialloyed structures with different shapes (including hollow NCs), surface coatings and dispersion environments that all can be customized depending on your needs. Prices will vary depending on the requested material and amount.

Please, take a look to our nanoparticles catalog: https://www.appliednanoparticles.eu/products/the-nanoparticles-atelier/

Applied Nanoparticles' Anniversary

In October 17, 2013 was constituted Applied Nanoparticles. "The society object is to research, study and development of nanoparticles and their applications. This includes but not limited to, the design, production and characterization, and consulting activities as well as outreach, training and education in nanoscience, nanotechnology and related areas"

Here are the milestones of Applied Nanoparticles: https://www.appliednanoparticles.eu/2017/06/02/milestones-of-biogasplus-by-applied-nanoparticles/

Until the July 14 of this year when Applied Nanoparticles announced the availability of BioGAS+ (beta version), a unique trace element additive for the optimisation of anaerobic digestion. This is a major milestone “inaugurating the nanomicrobiology era” !

Víctor Puntes, nanoscientist and founder of Applied Nanoparticles said:

“BioGAS+ is the result of intensive research that started in 2008 under the principles of Responsible Research and Innovation and will be marketed from next summer. Applied Nanoparticles offers the trace element supplement BioGAS+, a patented and registered nanotechnology-based innovation, that obtains the highest ever-reported improvement of biogas production. BioGAS+ contributes directly to the metabolism of microbes, with the doses of innocuous and bioavailable iron that needs the microbe at each moment. This is a paradigm shift in the prevalent solutions for optimization. The BioGAS+ enhancement lies on nanomaterial specifications, rather than material composition, a field which we dominate. We feel inaugurating the nanomicrobiology era. Anaerobic Digestion will never be the same.”

Applied Nanoparticles in The Biomethane Map

The European Horizon2020 project “Research Coordination for a Low-Cost Biomethane Production at Small and Medium Scale Applications”, short Record Biomap identifies different innovative process and technology solutions along the biomethane supply chain, from substrate pre-treatment, digestion and gas upgrading to biomethane, and aims to support their development up to market uptake. It has started on 1st of April 2016 and has a duration of two years. The project is coordinated by DBFZ - Deutsches Biomasseforschungszentrum gGmbH from Germany. The University of Warmia and Mazury (Poland) and the Swedish Institute of Agricultural and Environmental Engineering (JTI) are partners in this project.

From today, Applied Nanoparticles S.L. is live in The Biomethane Map and are in the stakeholders list. This means that will receive a newsletter, and we will be in contact regarding future workshops, presentations, and opportunities.

In the Map you can download the company profile and the technology description of Applied Nanotechnology developed BIOGAS+ technology.

BioGAS+ Prospectus

BioGAS+ Research Sample. 200 ml Flask of a Fe3O4 colloidal solution 10 mg/ml dispersed in a TMAOH 10 mM water solution.

What it is? BioGAS+ is the first ready to use additive based on safe and sustainable engineered iron based nanoparticles (NPs) directed to the optimization of anaerobic digestion processes which increases the production of Biogas and concentration of CH4.

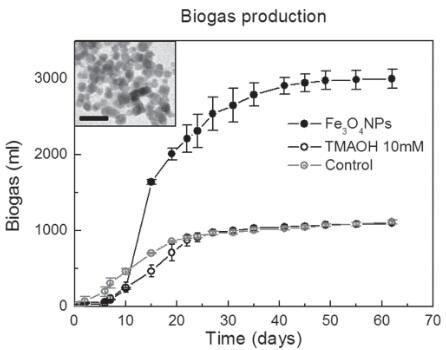

Applied Nanoparticles offers the trace element supplement BioGAS+, a patented and registered nanotechnology-based innovation that obtains the highest ever-reported improvement of biogas production (200%)1.

How it works? BioGAS+ contributes directly to the metabolism of microbes, with the doses of bioavailable iron that they need at each moment, for any microbe and for any feedstock. The mix (Fe2+/3+) iron oxide in its mineral form is rather inert in the working conditions but can provide bioavailable Fe2+ as a response to the electro-bio-mineral redox reactions and the expression of siderophore precursor genes. This is a paradigm shift in the prevalent solutions for Biogas Production optimization.

Instructions for use

Concentration: 10 mg/ml.

Recommended dose: 0,1% (w/w) vs VOC2 of waste to treat.

The provided amount is enough to treat 40 Liters of waste water at the 5% (w/w) of VOCs. Good results have also been observed with lower (0,01% vs VOC in w/w) doses.

Just add it up to your digester at any moment, for example along with your periodic fresh waste feeding.

For continuous digesters, we recommend an initial dose for the total digester volume and a recall daily dose proportional to the entrant waste.

BioGAS+ has shown different levels of performance which depend on the triad Nanoparticle-Microbiota- Organic Waste, the presence of sulphur and other chemical interferences, the different archaea in the different consortiums, the acclimatization time, etc

In our original studies we employed doses of the 10% of the VOCs following the standardized german DIN- 38414 Biomethane Production Test with cellulose and acclimatized inocula from an urban WWTP. Increments up to 200% of methane production were obtained. Further we observed that only a tiny fraction of our product was actually employed, so we kept decreasing the doses down to 0,01% while still observing production increments up to 30% in methane3

SHAKE VIGOROUSLY BEFORE USE. Materials denser than water materials tend to sink. Nanocrystals subjected to both Archimedes laws and Brownian Dispersion remain in solution but they may slowly sediment by entropic forces. This is reversible and the solution can be homogeneously recovered by hand shaking before use.

Storage and Disposal

Please keep it closed (it is sold preserved under N2 atmosphere) and use within 30 days once open. Otherwise we recommend aliquoting it in recipients without head-space to avoid oxidation of BioGAS+. Oxidation of BioGAS+ may result in a change of color of the solution (towards reddish-brown) and slower dissolution rate of the NPs, decreasing the effective released dose.

The product is safe and can be disposed as iron waste. If treated with a mild acidic solution in laboratory conditions it will be transformed in FeCl3. The product pH is slightly basic and the solution weakly buffered, therefore it should not pose any risk to the environment.

Safety

We consider the safety of our product during storage, use and disposal. Regarding the iron oxide nanoparticles, the product may be present as the original nanoparticles (BG+MSDS1), as microscopic iron oxide particles (aggregates) (BG+MSDS2) and as the derived iron Fe2+ (BG+MSDS3) and Fe3+ (BG+MSDS4) ions. Please refer to the provided BG+MSDS links. Additionally, refer to the report on the biological interactions of Fe3O4 nanoctrystals4. Regarding the dispersing solution, our TMAOH 10 mM has a pH of 11, therefore follow the usual precautions as when dealing with slighlty basic solution (BG+MSDS5).

1 Programmed iron oxide nanoparticles disintegration in anaerobic digesters boosts biogas production. Small, 2014, 10, 2801-2810.

2 Volatile Organic

Compounds.

3 In a lab/pilot

continuous digester at 37°C digesting sheep manure with 21 days resident time.

4Report on Safety and Toxicity of Iron Oxide Nanoparticle

BioGAS+ beta flyer

BioGAS+ is the first ready to use additive based on safe and sustainable engineered iron based nanoparticles directed to the optimization of anaerobic digestion processes which increases the production of biogas and concentration of CH4. Thus, the process that converts organic waste into raw matter for energy production is optimized by simply adding a small dose of iron based nanoparticles to either a large waste treatment reactor, a septic tank, or a homemade digester: you just spike the nanoparticles solution onto it.

BioGAS+ is a disruptive technology because it obtains the highest ever-reported improvement of biogas production: it triples (200% increase of production) the biogas yield with cellulose as feedstock in laboratory conditions and obtains over a 30% methane ratio increase in real industrial settings, with real feedstock and with optimal concentrations below then 0,1% (with respect to the Volatile Solids). Such a methane production increase is far above any known technology aimed at increasing biogas production. Many existing technologies as pre-treatment of the biomass, thermalization of the waste, combination of feedstock and inoculums only obtain modest production increases. Moreover, many tend to be costly to implement since they usually require structural changes in the biogas production process. The BioGAS+ technology is effective and easily implementable to any of the current waste treatment technologies and any of the previous. It is a solution that can be simply applied when the digester is fed or at any other convenient moment.

Biomass transformation into CH4 is one of the potential solutions to the pressing problems of mankind facing a decrease in mineral fuel resources, political instability, pollution and climate change. Global increase in (clean) energy demand, the need to improve organic waste processing towards a sustainable scenario and the Circular Economy are driving this transformation. Additionally it enable distributed solutions in situations or places out of the energy grid, favoring the implantation of tailored-size reactors fed with local biomass in isolated areas independently of sun shines or wind blows.

The beginning of the nanomicrobiology era. Nanomaterials can be designed to supply essential nutrients to the microbiota. Microbiota has the ability to extract ions from the mineral world and bring them to the biological world. By providing the essential ions in the pre-biotic form of a nanoparticle, we offer them an essential nutrients reservoir, so the microbiota can serve itself as much as it needs. This is critical in the case of iron. Such ionic dosing of iron from an instable mineral form is the base of Feraheme, a new already commercially available drug based on superparamagnetic iron oxide nanoparticles to treat anemia in humans1.

The beginning of the end of the organic waste. Applied Nanoparticles SL aims at promoting the use of organic waste as raw material for the production of biomethane and fertilizers, a contribution to prevent methane greenhouse gas emissions and obtaining green energy: Organic matter waste will rotten anyway, and this may send large amounts of methane to the atmosphere, a molecule with a 20 times greater greenhouse effect than CO2. Therefore, it is the responsibility of everyone, in order to create a cleaner planet with a more stable atmosphere, to prevent CH4 emissions and rather to introduce it into our cars and stoves?2

The beginning of sustainability era. Nanotechnology should drive us through the economy of the atom, the catalytic energy harvesting, the nanoengineered conversion and storage of energy and the catalyzed transformation of matter. All this taking us to an efficient and intelligent use of resources.

The unprecedented methane production increase, the universality of the technology –any microbe/any feed/any condition, iron always welcome- and its simplicity of use are the most appealing advantage of BioGAS+, but it also offers additional differential advantages, including:

i.- Better mass balance. As more carbon is transformed into CO2/CH4, also increases the CH4 ratio indicating a preference for recalcitrant matter and allowing to expand the available feedstock and rescue digesters in trouble.

ii.- Better energy extraction As there is more biogas, richer in biomethane, there is a reduced more degraded and more inert digestate with lower chemical potential after stronger digestion, enriched in iron, making it a nice fertilizer.

iii.- Beneficial chemical interference Capturing S, P, OH and tensioactive species improves and increases the stability of the process, After a delay time, likely for acclimatization, an acceleration and stabilization of the process has been recurrently observed.

iv.- Beneficial consortium fitting. While the dosing of iron makes the anaerobic consortium more robust, it also works well degrading other bacteria and therefore energy can be extracted from the consumed digester by adding BioGAS+ at later times (as far as it is still alive) and sanitation, elimination of pathogens is improved.

1 https://www.accessdata.fda.gov/drugsatfda_docs/label/2009/022180lbl.pdf

2 Please read our

Carbon-cycle chapter page 3 a 7 from “Starting up under RRI principles” by Nanowiki Editions.

The time has come! Inaugurating the nanomicrobiology era

Applied Nanoparticles announces availability of BioGAS+ (beta version)

Unique trace element additive for the optimisation of anaerobic digestion

Barcelona, 14 July 2017. In a new step from laboratory to market, with the purpose of making nanotechnology real, Applied Nanoparticles SL announces the availability of their patented, registered and unique product, BioGAS+, that obtains the highest ever-reported improvement of biogas production, among many other differential advantages1.

The trace element additive BioGAS+ contributes directly to the metabolism of microbiota. Based on innocuous iron oxide nanocrystals that dissolves at the demand of archaea in order to boost their metabolic activity, increasing thus biomethane production and keeping a healthy consortium stabilizing your process. The increased biomethane production is concomitant with a reduction of the digestate volume and its chemical potential (reactivity), and the final digestate is enriched in iron ions, being a better fertilizer. Increased anaerobic digestion also translates into an increased sanitation and process acceleration. Additionally, iron ions precipitate S and P species and attenuates pH variations. Interestingly, BioGAS+ has been observed to promote the degradation of recalcitrant matter and rescue of “sick digesters”. The ability of nanoparticles to absorb tensioactives resulting on reducing foams has been also observed. This is a paradigm shift in the prevalent solutions for optimization of biogas production. BioGAS+ is developed under the principles of Responsible Research and Innovation (RRI)2. The technology is safe and environmentally friendly, contributing to sustainable energy production and waste management. It produces not only greener energy but also greener digestate (ready to be compost). Anaerobic Digestion will never be the same.

Recently, there has been a general turn in the European Union towards green energies (the one that started with the “Energiewende”). Governments are pushing for renewable energy infrastructure and production. By 2020, 20% of the energy consumed in the EU will be renewable (2009/28/CE).

When we first observed the effects of Fe3O4 nanoparticles (NPs) in anaerobic digesters we did not really realize what was happening. We were studying the inhibition potential of inorganic NPs and their toxicity to anaerobic consortia in wastewater treatment plants (WWTPs) in the framework of a research project of the Spanish Ministerio de Medio Ambiente y Medio Rural y Marino, where biogas production/inhibition was an endpoint to test NP toxicity. Our results published in Journal of Hazardous Materials3 and Smalli showed that non silver or gold or TiO2 NPs had any negative effect, CeO2 NPs produced inhibition of biogas production likely due to the Ce3+ ions, and an increase of production in the case of Fe3O4. Indeed, an external colleague was who pointed it out saying: “Hey guys, you are triplicating biogas production! This is way above anything I have ever seen!”

This let us confused for a while. It could be an artifact, but normally, when something goes experimentally wrong, you get less biogas, not more...Then we started reproducing the experiment, developing models and adding controls until the phenomena was slightly understood (so we could take a direction to evolve): Dosing at the Nanoscale.

Dosing at the nanoscale is a principle translated from current pharmacology and drug delivery technology. For example, to treat ferropenic anemia in some conditions, patients are injected large amounts of pre-biotic (mineral) iron (amounts that in the ionic form would be toxic) that slowly transform inside the body into Fe2+ biologically beneficial ions. BioGAS+ is an analogue approach to treat the endemic ferropenic anemia of archaea.

Once the trail was drawn, things speeded up: getting a patent, looking for and obtaining funding, scaling up the production of the NPs, scaling up the application of the NPs; and doing it all under safety by design and RRI principles. After the initial academic research we obtained funding from the Bill and Melinda Gates Foundation. A Patent was deposited in Europe by patent application 12707361.7.1352 Ref. P1923EP01/EP2683662 and in the USA by patent application nr. 14/004.646 and publication nr. 2014/0017753. Priority Data: 11/03/2011. We were given a Secretaria General Iberoamericana prize in 2013. Our description of the observed phenomena was accepted for publication in the specialized journal Small1. In 2013 the patent was made public. Then we obtained strong support from Repsol Foundation for two years incubation and we succeeded in industrializing the production of our nanoparticles and moving our biogas production tests from batch to semicontinuous pilots replica of anaerobic industrial digesters.

Today, the world of biogas is big and complex We need co-developers, indeed. We hope that we will create a community of optimized AD where NPs can play many beneficial roles. Therefore, we are selling it at production costs and at amounts dimensioned for research purposes.

We will start accepting orders in September 2017 (all details will be explained in BioGAS+ website: https://biogasplus.info), they will enjoy of a special beta version price and it will be served in a first in, first out basis.

Recently, Víctor Puntes, nanoscientist and founder of Applied Nanoparticles said:

“BioGAS+ is the result of intensive research that started in 2008 under the principles of Responsible Research and Innovation and will be marketed from next summer. Applied Nanoparticles offers the trace element supplement BioGAS+, a patented and registered nanotechnology-based innovation, that obtains the highest ever-reported improvement of biogas production. BioGAS+ contributes directly to the metabolism of microbes, with the doses of innocuous and bioavailable iron that needs the microbe at each moment. This is a paradigm shift in the prevalent solutions for optimization. The BioGAS+ enhancement lies on nanomaterial specifications, rather than material composition, a field which we dominate. We feel inaugurating the nanomicrobiology era. Anaerobic Digestion will never be the same.”

About Applied Nanoparticles SL

Applied Nanoparticles SL (AppNPs) is a technology-based spin off company derived from the Universitat Autònoma de Barcelona (UAB), the Institut Català de Recerca i Estudis Avançats (ICREA), and the Catalan Institute of Nanoscience and Nanotechnology (ICN2). The company was founded on October 17th 2013. The company's purpose is to research, study and develop nanoparticles and their applications. This includes design, production and characterization of nanoparticles, consultancy activities and dissemination, as well as training and education in nanoscience, nanotechnology, and related areas under principles of Responsible Research and Innovation. AppNPs core project is the commercial exploitation of a EU-US patent, BioGAS+. AppNPs ultimate aspiration when developing BioGAS+ is to transform waste into appealing raw materials in an efficient and sustainable way while contributing to key policy objectives, such as climate change targets, energy and food security, resource efficiency, improved air quality, the bioeconomy, bioenergy, the prevention of contamination and develop circular economy. You can find out more information from our website: https://www.appliednanoparticles.eu/

Context

We have chosen this date, 14 July, as our humble homage and recognition to the Age of Enlightenment.

Contact

To learn more about this announcement, please contact info@appliednanoparticles.eu

1 Programmed iron oxide nanoparticles disintegration in anaerobic digesters boosts biogas production. Small, 2014, 10, 2801-2810.

2 https://innovation-compass.eu/wp-content/uploads/2017/04/AppNPs-Final.pdf

3 Effect of cerium dioxide, titanium dioxide, silver, and gold nanoparticles on the activity of microbial communities intended in wastewater treatment Journal of Hazardous Materials 2012, 199, 64– 72.

Unique trace element additive for the optimisation of anaerobic digestion

Applied Nanoparticles Receives the Highly Commended Award for Research Project

Charlotte Morton, Chief Executive of ADBA, said: "UK AD & Biogas Awards 2017 was a fantastic celebration of talent and innovation in our industry. Congratulations to all those who received an award; the standard this year was exceptionally high, which is excellent news given the scale of the contribution the AD industry can and needs to make urgently to the Paris climate change commitments and UN Sustainable Development Goals."

Applied Nanoparticles SL received the Highly Commended Award for Research Project.

We are incredibly proud to have been rewarded. Víctor F. Puntes, nanoscientist and founder of Applied Nanoparticles said: “BiogasPLUS is the result of intensive research that started in 2008 under the principles of Responsible Research and Innovation and will be marketed from next summer. Applied Nanoparticles offers the trace element supplementation BiogasPLUS, a patented and registered nanotechnology-based innovation, that obtains the highest ever-reported improvement of biogas production. BiogasPLUS contributes directly to the metabolism of microbes, with the doses of innocuous and bioavailable iron that needs the microbe at each moment. This is a paradigm shift in the prevalent solutions for optimisation. We feel inaugurating the nanomicrobiology era! Anaerobic Digestion will never be the same.”

About Applied Nanoparticles SL

Applied Nanoparticles SL (AppNPs) is a technology-based spin off company derived from the Universitat Autònoma de Barcelona (UAB), the Institut Català de Recerca i Estudis Avançats (ICREA), and the Catalan Institute of Nanoscience and Nanotechnology (ICN2). The company was founded on October 17th 2013. The company's purpose is to research, study and develop nanoparticles and their applications. This includes design, production and characterization of nanoparticles, consultancy activities and dissemination, as well as training and education in nanoscience, nanotechnology, and related areas under principles of Responsible Research and Innovation. AppNP’s core project is the commercial exploitation of a EU-US patent named BiogasPLUS. BiogasPLUS is the frst ready to use additive based on safe and sustainable engineered iron based nanoparticles for the optimization of anaerobic digestion processes. BiogasPLUS is a disruptive technology as it obtains the highest ever-reported improvement of biogas production, triples the biogas yield with cellulose as feedstock in laboratory conditions, and obtains over a 30% methane ratio increase in real continuous industrial settings, among other additional advantages. AppNP’s ultimate aspiration when developing BiogasPLUS is to transform waste into appealing raw materials in an effcient and sustainable way while contributing to key policy objectives, such as climate change targets, energy and food security, resource effciency, improved air quality, the bioeconomy, bioenergy, and the prevention of contamination and develop circular economy.

About AD & Biogas Industry Awards 2017

Back for the sixth year running, the 2017 AD & Biogas Industry Awards will showcase the very best plants, successes and people across the AD industry, both in the UK and around the world.

Related information:

May 2017, BiogasPLUS by Applied Nanoparticles shortlisted for AD & Biogas industry award

June 2017 Milestones of BiogasPLUS by Applied Nanoparticles

The time has come. The countdown...

Sunday, 9 July, 2017: The time has come. Applied Nanoparticles will make an important announcement this week. The countdown begins ... five days left!

Context: The anti-enlightenment movement has reached the White House but...“A strong economy and a healthy planet are mutually reinforcing.... We remain collectively committed to mitigate greenhouse gas emissions through, among others, increased innovation on sustainable and clean energies...We take note of the decision of the United States of America to withdraw from the Paris Agreement... The Leaders of the other G20 members state that the Paris Agreement is irreversible” #G20 #climatechange #renewables #anaerobicdigestion https://www.g20.org/gipfeldokumente/G20-leaders-declaration.pdf

Monday, 10 July 2017.The countdown follows... four days left!

A man of Enlightenment, Alessandro Volta, was the first to isolate methane. He also discovered methane mixed with air could be exploded using an electric spark: this is the basis of the internal combustion engine. The name "methane" was later coined by August Wilhelm von Hofman

“They made it! Inspiring testimonial from a company which integrated #RRI principles in their activity: Applied Nanoparticles SL.” It is the responsibility of everyone, in order to create a cleaner planet with a more stable atmosphere, to prevent CH4 from entering the atmosphere and rather to introduce it into our stoves, vehicles and heaters. We understand #RRI as a normative-political orientation that seeks to alter the present sociotechnical order; we are convinced that taking a Responsible Research and Innovation approach to research is the only way of solving the problems we have in the world https://innovation-compass.eu/wp-content/uploads/2017/04/AppNPs-Final.pdf

Tuesday, 11 July 2017. The countdown follows... three days left!

Wednesday, 12 July 2017. The countdown follows... two days left!

“When we first observed the effects of Fe3O4 nanoparticles in anaerobic consortiums digestions we did not realize what was happening.” Discovery of Magnetite Nanoparticles role on Anaerobic Digestion (2010). Scientifc Publication of phenomena (2014).

“A novel concept of dosing iron ions using Fe3O4 engineered nanoparticles is used to improve biogas production in anaerobic digestion processes. Since small nanoparticles are unstable, they can be designed to provide ions in a controlled manner, and the highest ever reported improvement of biogas production is obtained. The nanoparticles evolution during operation is followed by an array of spectroscopic techniques” http://onlinelibrary.wiley.com/doi/10.1002/smll.201303703/abstract

Thursday, 13 July 2017. The countdown follows... one day left!

Differential advantages of BiogasPLUS by Applied Nanoparticles

BiogasPLUS is the first ready to use additive based on safe and sustainable engineered iron based nanoparticles directed to the optimization of anaerobic digestion processes which increases the production of biogas and concentration of CH4. Thus, the process that converts organic waste into raw matter for energy production is optimized by simply adding a small dose of iron based nanoparticles to either a large waste treatment reactor, a septic tank, or a homemade biodigester, you just spike the nanoparticles solution onto it.

BiogasPLUS is a disruptive technology because it obtains the highest ever-reported improvement of biogas production: triples (200% increase of production) the biogas yield with cellulose as feedstock in laboratory conditions and obtains over a 30% methane ratio increase in real industrial settings, with real feedstock and with optimal concentrations below the 1% (with respect to the Volatile Solids). Such a methane production increase is far above any known technology aimed at increasing biogas production: many existing technologies approach this problem (i.e. pre-treatment of the biomass, thermalization of the waste, combination of feedstock and inoculums) but only obtain modest production increases. Moreover, many tend to be costly to implement since they usually require structural changes in the biogas production process. The unprecedented methane production increase is the most appealing advantage of BiogasPLUS, but it also offers additional differential advantages, including:

1. Increase in both biogas and biomethane production.

2. Improving biomass to biomethane conversion effciency.

3. Better biogas composition (higher methane share).

4. Reduction of the digestate fraction (more biogas means more digestion).

5. Higher waste degradation (the digestate is less, and less reactive).

6. Increase digestion process stability (more reproducible).

7. Acceleration of the digestion process. Reduction in retention/residential time.

8. Proven to reduce H2S levels (precipitated in the form of pyrite).

9. Reduction on the amount of foam produced (small particles trap detergents decreasing foam).

10. Enrichment of the residual material (digestate) with iron ions to obtain by-products with increased economic value such as high quality fertilizers.

11. Solution to inhibitory substances. Rescue of digesters with problems.

12. Simple additive that can be just spiked onto the incoming sewage (it does not require any change in the biogas plant industrial process).

13. It does not require pre-treatment of the substrate/feedstock or maintenance to preserve the microorganisms.

14. Enlargement of biomass feedstock (oil, fat, meat) as it has been proved very suitable for “diffcult to digest” (recalcitrant) feedstock.

15. Enlargement of biomass feedstock (low energy waste) due to the increased biogas/methane production.

16. Can be used with any kind of anaerobic digester, the process is fully scalable.

17. Reduce AD plant energy consumption.

18. Minimize undesirable side effects in biogas plants such as the odours associated to HS and NH3, thus reducing the cost of associated conditioning measures.

19. Precipitation (recovery) of phosphorus (in the form of ferric and ferrous phosphate).

20. Disinfection of pathogens and multi-resistant bacteria.

Milestones of BiogasPLUS by Applied Nanoparticles

BiogasPlus is inaugurating the era of nano-micro-bio-technology. Innocuous iron oxide nanocrystals dissolve at the demand of methanogenic archaea in order to boost their metabolic activity increasing thus biomethane production and: the increased biomethane production is concomitant with a stabilization of the process and a reduction of the digestate volume and reactivity; the fnal digestate is enriched in iron ions being a better fertilizer. Increased anaerobic digestion translates into an increased sanitation and process acceleration. Reducing foam due to its particulate nature, keeping a healthy the bacterial consortium, promotes degradation of recalcitrant matter and rescue of sick digestors. Iron also precitpitates SH and P and atenuates pH increase.

2008. Grant Spanish Environmental Ministry. Nanoclean Up. The use and the effects of nanoparticles (NPs) in waste water treatments.

2010. Discovery of Magnetite NPs on Anaerobic Digestion.

2011-2013. Grant from Bill and Melinda Gates Foundation: Increase of biogas production using low-cost nanoparticles

2011. Patent deposited in the EU and US This method is being protected in Europe by patent application 12707361.7.1352 Ref. P1923EP01/EP2683662 and in the USA by patent application nr. 14/004.646 and publication nr.2014/0017753. Priority Data: 11/03/2011

2012-2013 Fundación Repsol Award Cathegory IDEA

2013 Applied Nanoparticles is created.

2013 Secretaria General Iberoamericana, 2nd Innovation Prize

2013 Patent made public 20/09/2013

2014 Scientifc Publication of the phenomena: Programmed Iron Oxide Nanoparticles Disintegration in Anaerobic Digesters Boosts Biogas Production

2014-2016 Fundación Repsol Award Category INNOVATION

2014-2016 2015 MINECO bussines plan AWARD

2016 Industrial Production of BiogasPLUS reached and subcontracted

2017 First satisfactory results in continuous treatments in Pilot Plants.

2017 February COMPASS AWARD for Responsible Research and Innovation

2017 May Applied Nanoparticles SL shortlisted for the 2017 AD & Biogas Industry Awards in the Research Project category Awards announced on july 5, 2017 in the #1 global tradeshow for biogas: Applied Nanoparticles Receives the Highly Commended Award for Research Project

BiogasPLUS by Applied Nanoparticles shortlisted for AD & Biogas industry award

Applied Nanoparticles SL are excited to announce that we have been shortlisted for the 2017 AD & Biogas Industry Awards in the Research Project category!

These annual Industry Awards showcase the best of the best in innovation and achievement across all sectors of the AD and biogas industries both in the UK and globally, and we are incredibly proud to have been nominated.

Víctor F. Puntes, nanoscientist and founder of Applied Nanoparticles said:

“BiogasPLUS is the result of intensive research that started in 2008 under the principles of Responsible Research and Innovation and will be marketed from next summer. Applied Nanoparticles offers the trace element supplementation BiogasPLUS, a patented and registered nanotechnology-based innovation, that obtains the highest ever-reported improvement of biogas production. BiogasPLUS contributes directly to the metabolism of microbes, with the doses of innocuous and bioavailable iron that needs the microbe at each moment. This is a paradigm shift in the prevalent solutions for optimisation. We feel inaugurating the nanomicrobiology era! Anaerobic Digestion will never be the same.”

Charlotte Morton, Chief Executive of the Anaerobic Digestion & Bioresources Association, said:

“We’re honoured to recognise the exceptional contributions our shortlisted award entries have made to the AD industry both in the UK and around the globe. Their dedication to enhancing our industry’s reputation and performance is testament to the innovative and entrepreneurial spirit that has built the AD industry in the UK and abroad today, which is poised to make a huge contribution to meeting some of the world’s most pressing challenges.”

David Newman, President of the World Biogas Association, said:

“Those who have been shortlisted for these awards represent the very best of the best in innovation and best practice in AD and biogas from around the world, and serve as a shining example of how biogas can help to meet the UN Sustainable Development Goals. This is an exceptional industry delivering exceptional value on a global scale.”

The winners will be announced on 5 July during a gala dinner at the NEC in Birmingham on the first night of UK AD & Biogas and World Biogas Expo 2017, the leading global tradeshow for biogas.

About Applied Nanoparticles SL

Applied Nanoparticles SL (AppNPs) is a technology-based spin off company derived from the Universitat Autònoma de Barcelona (UAB), the Institut Català de Recerca i Estudis Avançats (ICREA), and the Catalan Institute of Nanoscience and Nanotechnology (ICN2). The company was founded on October 17th 2013. The company's purpose is to research, study and develop nanoparticles and their applications. This includes design, production and characterization of nanoparticles, consultancy activities and dissemination, as well as training and education in nanoscience, nanotechnology, and related areas under principles of Responsible Research and Innovation. AppNP’s core project is the commercial exploitation of a EU-US patent named BiogasPLUS. BiogasPLUS is the frst ready to use additive based on safe and sustainable engineered iron based nanoparticles for the optimization of anaerobic digestion processes. BiogasPLUS is a disruptive technology as it obtains the highest ever-reported improvement of biogas production, triples the biogas yield with cellulose as feedstock in laboratory conditions, and obtains over a 30% methane ratio increase in real continuous industrial settings, among other additional advantages. AppNP’s ultimate aspiration when developing BiogasPLUS is to transform waste into appealing raw materials in an effcient and sustainable way while contributing to key policy objectives, such as climate change targets, energy and food security, resource effciency, improved air quality, the bioeconomy, bioenergy, and the prevention of contamination and develop circular economy.

About AD & Biogas Industry Awards 2017

Back for the sixth year running, the 2017 AD & Biogas Industry Awards will showcase the very best plants, successes and people across the AD industry, both in the UK and around the world. With a range of categories reflecting the growth of the sector, and featuring two new categories recognising achievement in sewage treatment, this is an opportunity to see projects, services, teams and people given the recognition they deserve. The event will take place in Birmingham on 5 July – the first night of UK AD & Biogas and World Biogas Expo 2017, the #1 global tradeshow for biogas.

Just posted the April 2017 BioGAS+ Newsletter by Applied Nanoparticles

For the optimisation of anaerobic digestion, Applied Nanoparticles is developing the trace element supplementation BioGAS+, a patented and registered nanotechnology-based innovation that obtains the highest ever-reported improvement of biogas production. BioGAS+ contributes directly to the metabolism of microbes, with the doses of bioavailable iron that needs the microbe at each moment. This is a paradigm shift in the prevalent solutions for optimisation.

As we take the last steps from the laboratory to the market and putting our solution in context, Applied Nanoparticles publishes a BioGAS+ Newsletter, a monthly compilation and

overview of cutting-edge anaerobic digestion industry news in the context of global energy transition and new multipolar world.

April Contents: 2020, The Climate Turning Point: experts identify the year 2020 as a game changing opportunity to turn the tide on the devastating impacts of carbon emissions;

the next four years are critical to the future of our planet | Potential of biogas from digestion in EU beyond 2020: biogas can be a flexible and sustainable alternative source of energy, which

supports energy security and greenhouse gas emission reduction in electricity, heating and transport | How digitalization is changing energy markets: entering the brave new world of the energy,

“the new internet”

We track the biogas world in a daily basis in the BioGAS+ twitter account and we compile all information related with our coming product in the BioGAS+ website.

Applied Nanoparticles Celebrates The World Book Day

We wish to share with you some free ebooks (and videos) that contributes to the public divulgation of the nanoscience and nanotechnology. Alternatively, you can also buy paper editions of this books.

All of them where written and illustrated by some of the co-founders of Applied Nanoparticles, and are publicly accesible in the Internet Archive, a non-profit library that offers permanent access for researchers, historians, and scholars to historical collections that exist in digital format.

Access to this collection of nanoscience and nanotechnology ebooks (and videos) here.

This time we highlight the book “Nano-Oncology, the Turning Point: Discover the Wave of Knowledge that Makes Fighting Cancer with Nanotechnology Real” by Pr. Victor Puntes and Josep Saldaña Cavallé, and designed by Joan Escofet; with foreword by Simò Schwartz and contribution by Miriam Varon.

Just a little quote from the foreword by Simo Schwartz, Director Cibbim-Nanomedicine, Vall d'Hebron Institut de Recerca (VHIR): “If nanotechnology refers to the design, production and application of structured materials, devices and systems at the nanometric scale, nanomedicine refers to their uses in diagnostics and treatments in the medical practice. Far from the public perception that nanotechnology and nanomedicine are still trending topics of science fiction, a new emerging reality is deepening its roots in our society and people begins to realize that a new giant wave is going to smash our shores in the form of a technological revolution... and the impact might even go beyond imagination.”

Enjoy the reading!

Responsible Nano Breakfast in Brussels

The first RNB (Responsible Nano breakfast) took place on the 1st of March morning in Brussels organized by COMPASS European-funded project that supports Small and Medium-sized Enterprises (SMEs) or businesses in three emerging technology industries to manage their research, development and innovation activities in a responsible and inclusive manner

Our case study was one of the winners: “They made it! Inspiring testimonial from a company which integrated RRI principles in their activity: Applied Nanoparticles SL”

Here you can read the post Spinning off under RRI Principles: BioGAS+ by Applied Nanoparticles SL explaining our endorsement of Responsible Research and Innovation in practice